Instrumentation and Data Recording

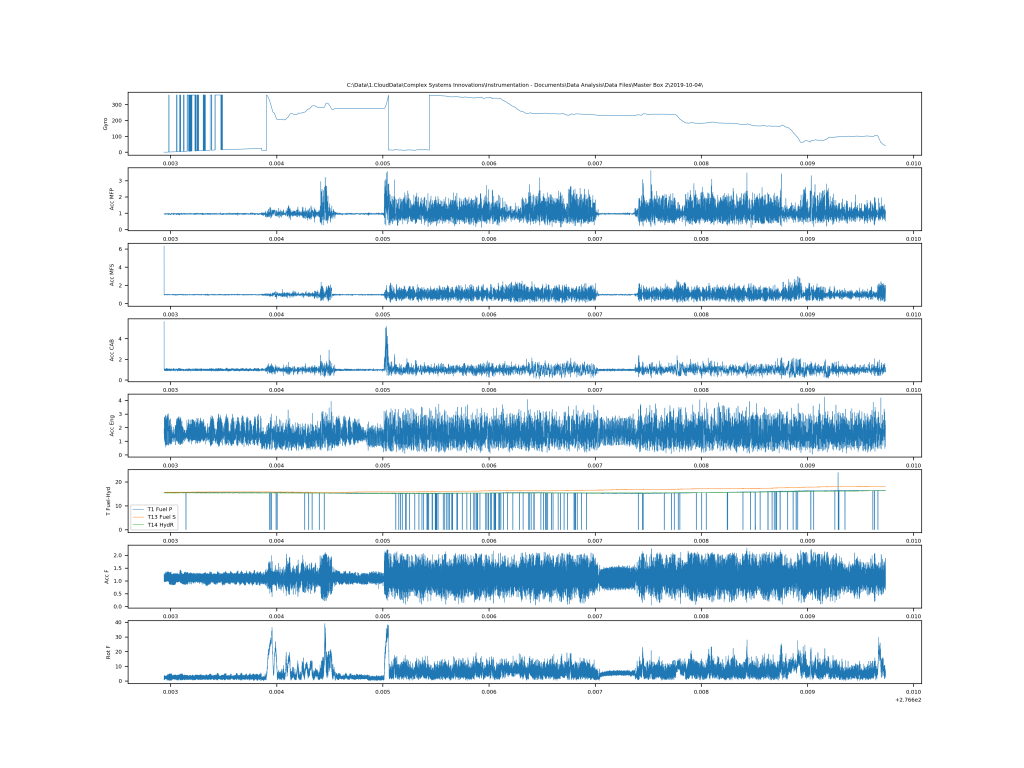

The challenge was quite a big one; to fully instrument and collect performance data on two prototype vehicles using something over 100 data channels on one vehicle, 60 on the other, polled at intervals between 2 and 1000 Hz for test sequences in excess of 8 hrs in extremes of temperature. We couldn’t find anything that would do the job at a sensible price so we designed and commissioned our own.

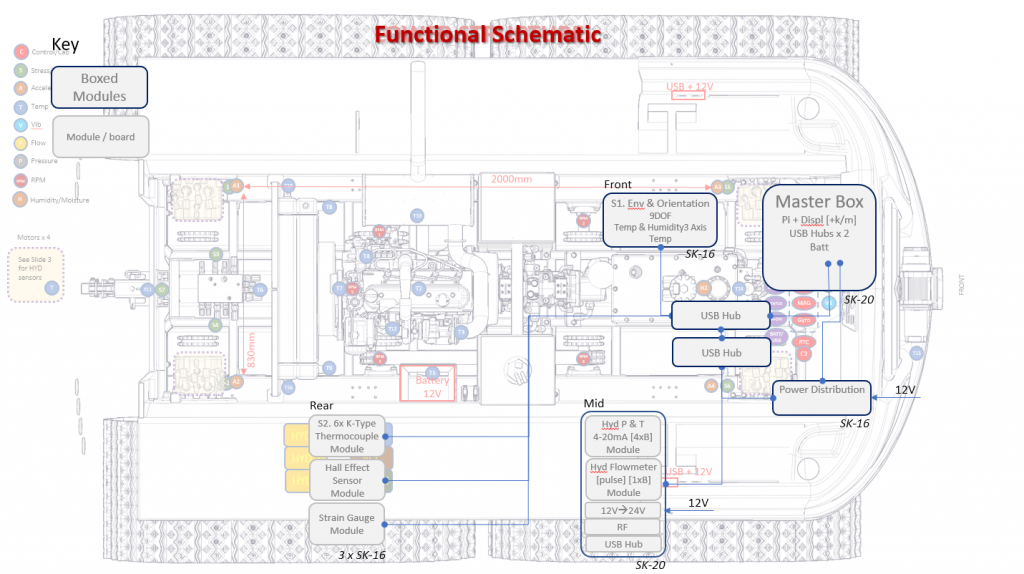

The system we built utilises a microprocessor-based master controller polling a distributed set of micro-controller collection hubs. Each hub is optimised to decode a set of sensor types, which are buffered locally and read to the master store on the master box. A Linux operating system allows for a variety of on-board functional apps and transfer of data via a remote link.

Wherever possible we have utilised encapsulated off-the shelf sensors to keep prices down and allow us to deploy sensor sub-sets cost-effectively onto a number of test vehicles. This approach has worked well, providing a highly flexible, accurate and cost-effective solution.

The monitoring system now provides the basis for a more compact diagnostic set and a cut-down versions will be utilised as part of the on-board instrumentation set for future hybrid and autonomous variants .

A repackaged version will be be made available for sale as a general purpose data collection and test set in due course.